There were issues with the last test part. The rubber was still too soft with the 60A blend and the airbox would try to fall off when I rode. The plan was easy, just get the next harder rubber and make another. Well, thing is, that was the hardest rubber they made in that compound so I switched to a different compound that was rated at an 80A hardness. And hell yea it’s clear!

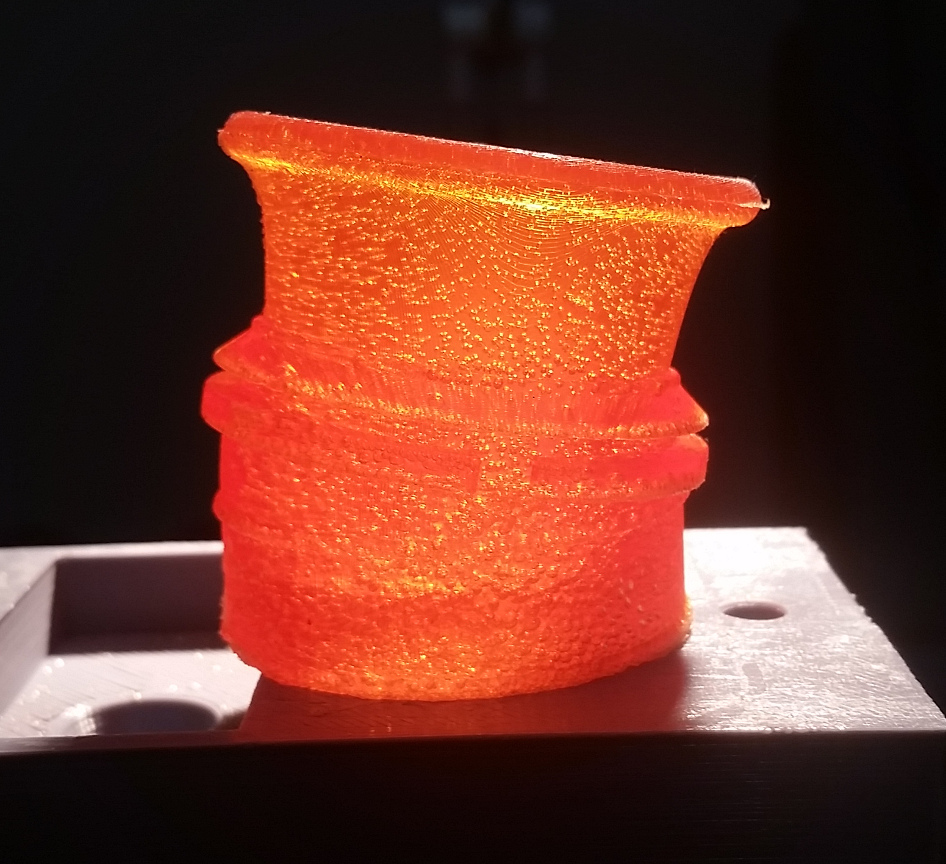

But it shined a light upon my deeper issues. It was full of bubbles. Stupid, spongy bubbles. The internets said I needed to either try to degas the liquid or to mold it under pressure. Well I had an air compressor and I didn’t have a vacuum pump so solved that riddle pretty quickly. I was pointed to a 2.5 gallon high volume paint sprayer pot to use from numerous sources from the Freight, but they were out so I found an equivalent on Amazon. One trip to the hardware store and it was an easy conversion to be just a pressure pot instead of one designed to project paint. Now I can just fill the mold, put it in the pot, pressurize it, then come back the next day.

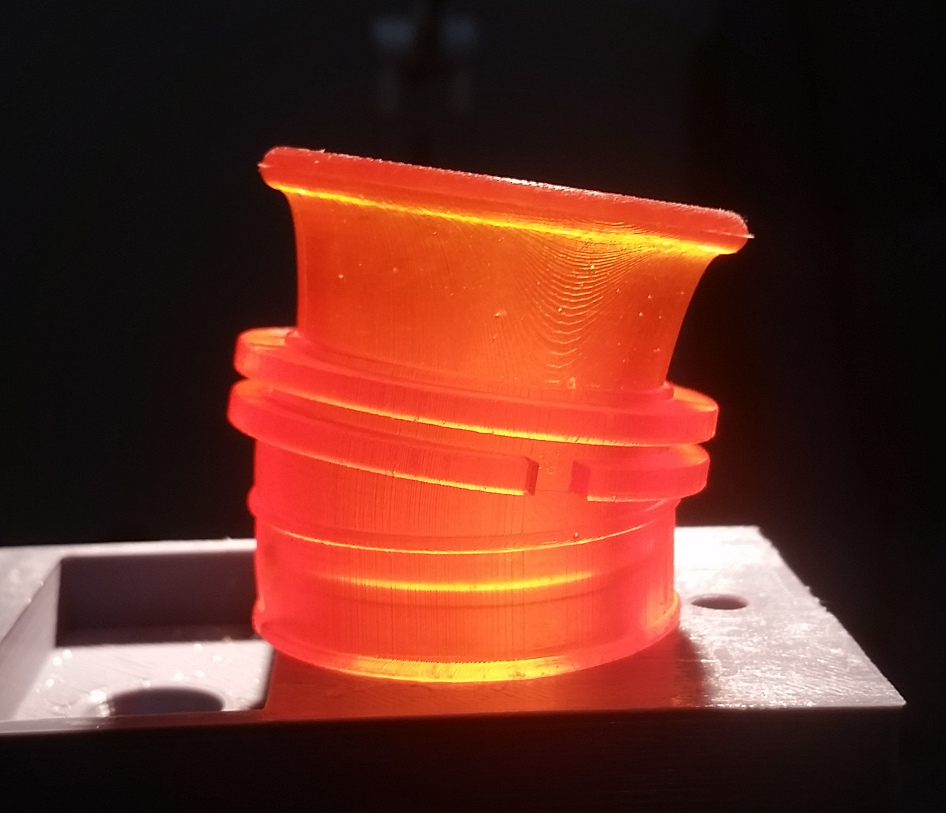

The next thing to address was the lip that retains the airbox. The first draft was based on the stock part but I made a couple of errors. The stock part is mostly solid with a small hole in the center and it was a pretty hard rubber. With the same shape but hollow it looses a lot of rigidity and the softer rubbers I was using was a double blow to the whole “not falling off in the street” thing. Quick redesign of those parts, reprint the mold and we good to go.

Now we are doing real, honest iterative design. On a moped part! No one ever does that. These woods have no man made signs, I will have to travel by wit alone. Luckily I’m chock full.

This part finally felt good. The first one I could hand someone without explaining how I’m going to fix it in post. No bubbles, no more spongy feel, rubber felt correct finally, the airbox fit was solid, it just felt like I was getting somewhere. I didn’t even have to zip tie the airbox on for the test ride. Next step is to make a handful and give them out for long term testing. Got some other big plans too so stay tuned!