So the Puddle Cutters, like many clubs do, raffle a bike during our rally weekend. I usually volunteered to build them because it’s fun and I take a bit of pride in it. A raffle, at it’s core, should be fun. Everyone is excited, they scream and yell and throw spent tickets on the ground and one person gets to live a bit of the dream. And when they go over to start the bike and everyone yells it’s fun to know I’ve helped with that. I’ve built about 10 raffle bikes and while the building might be stressful, the payoff is worth it.

From the clubs perspective it’s a logistics game. Do you plan on making money on the raffle? What’s the budget for the bike? Timeline? Who’s helping? What is around to use? What can you get donated? It takes a lot more thought and planning than people expect. Always a lot more effor than people assume at the start. It’s very easy to not plan enough time ahead, budget enough money, or scrounge up enough parts and have problems delivering a running bike to the raffle. One of my raffle bike building rules is not only does it have to run but I also have to ride it during the weekend. If you get passed on the Saturday long ride by the raffle bike damn right you’re buying more tickets. It gets people excited. No disappointments.

We had a budget of $300 for the bike. I was going to donate a bike that I had sitting around and then build what I could. It needed to be fast, not boring, and maybe even look good. Well, that last one was a stretch. I was starting with a Honda Aero 125 so making it look good was a pipedream on a budget like that. But I could make it faster. And at least interesting. That counts for something.

A note on the base bike. I had such high hopes for the Aero 125. Honda sold it for one year only and I’m pretty sure I know why. It’s terrible. A 125cc 2-stroke auto scooter with a cvt should have been so damn cool. Everything about it is just a bummer though. It’s half a horsepower more than the Elite 150 of the same year, size and cost, with less fuel economy, pulls a meager 50-55mph flat out, doesn’t do it with any sort of flair, and the front suspension is awful. I bought it for $150 and it was in really good shape but man, I hated it. Perfect for such an endeavor.

So I had the bike, but what to do with it? Well it needed to be faster, it needed better front suspension and brakes, and make it interesting looking for $300. I got this.

First was the front end and I had a plan. A customer abandoned a Kymco Super 8 in my shop with a blown up motor and I gave it to a friend for parts. He moved and left the bike in the yard behind the old apartment. A year later I called him up and he told me where the apartment was. Damn thing was still there. I took it, stripped the front end out of it and junked the rest. That supplied me telescoping forks, big front wheel, and disc brakes. I was working at a machine shop at the time so I fabbed up some stainless steel fork bearing adapters to go from the Aero frame to the Kymco bearings. It took some fork tube modifications but it was all press together when it was done. This also gave the bike a small bit of rake and gave it a good stance. Honestly it’s the best thing I did to the whole bike.

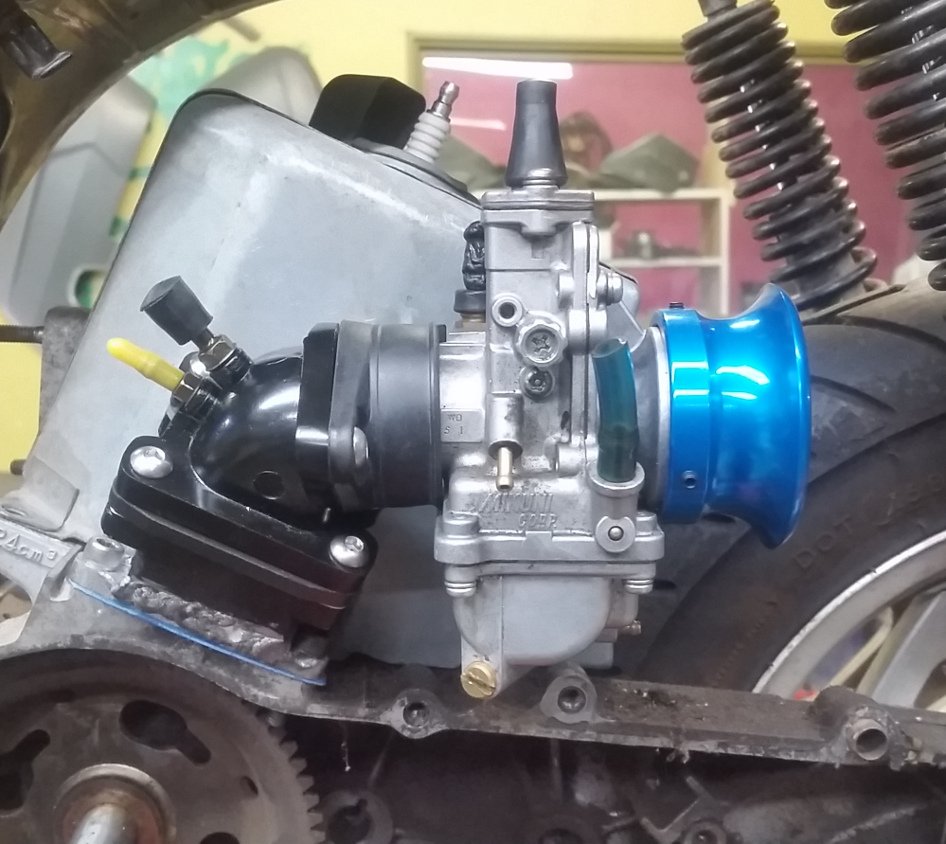

Next was the motor. And damn did they not make parts for it at all. Not a single performance part anywhere. I read that some people put old CR125 pistons in them and bored out the cylinder a little but it’s not even worth it. Factory specs were redline at 7500 rpms with a 14mm carb, and no expansion chamber, so pretty restricted overall. The basic plan was to port the cylinder, add a better reed system and larger carb, an expansion chamber, some transmission parts, and replace the cdi box in case it had a limiter. I wanted a higher top speed but there was no way to change the drivetrain gearing and no aftermarket transmission parts so the only way was to raise the rpm ceiling. The stock port timings were very mild so I built a base plate shim, decked the top of the cylinder off, and modified the exhaust port to get around 122 transfer timing and 180 exhaust. I left the stock head alone so the compression stayed the same. I bought a standard dio 4 pedal adapter from NYC and grabbed a TM24 I had sitting around. Of course the dio bolt pattern was different than the Aero 125 so I cut the stock intake plate off and welded it to the bottom of the new reed block. The exhaust was actually interesting. Originally built custom for an 80’s vespa smallframe racer, it was gifted to this project to but cut up as needed. In theory it should be sized correctly for the displacement and be roughly the rpm window but in practice it really didn’t do much. It did look real cool though. I had to cut and rotate it a couple of times to get it to fit but it was pretty strait forward. The clutch and bell were worn out but luckily the input shaft for the rear trans had the same splines as the other honda scooters. I was able to mount a 107mm bell with a small shim and a cheap aftermarket 107mm clutch to the stock Aero rear pulley. I also used a cheap no limit cdi and that was it for the motor.

The budget was pretty much shot. The forks were free, the machining was free, the labor was free. The motor parts? Well Scooter Swap Shop helped with cheap parts but they pretty much took all of it. So I had a plastic scooter that I can’t fit any of the panels on because of the different front end and the motor mods and no money to do anything about it. So I said to hell with the plastic. But with no plastics I needed a way to mount headlights. I had left all the mounting tabs on the Super 8 handlebars including a large tab on each side, and I had two square fog lamps that bolted into the holes perfectly. I mounted them up and when I stood back I realized they were eyes. Perfect, it gets a face. I called Bob and gave him freedom to make a face to bolt to the front with the headlights being the eyes. It was weird but it was unique and that’s worth more than most things to me. With no plastics there was actually nowhere to put your feet so I welded in a piece of tubing for your feet. I moved the rear foot brake to be usable with the new foot pegs. I had to build a retainer for the battery box as well since that was also part of the plastic that was discarded. Basically there was a lot of work in little stupid logistics aspects of the frame you don’t notice but make it function. I cut a flat board to fit over the gas tank and hinged it on the old seat and had a friend put some sweet sparkle blue material on it. There was the usual bunch of details like new wiring harness, cables, hydraulics, tuning, ect.. that needed to make it a functional bike but it was honestly less work than some of the previous raffle bikes. Hell it was even done a couple days before the rally which was a big win.

How did it run? Actually pretty well. The motor wasn’t super powerful but much better than stock with a smooth power delivery. There was no noticeable powerband which I blame on the pipe probably not doing much other than looking cool but the new top speed was around 75mph, which was a huge improvement. The new front end and brakes made it a really smooth ride that handled pretty good. I led the Saturday long ride on the bike for about 80 miles and it handled it with no issues. Overall I was pretty happy with it considering the budget and time constraints. Would I ride it around? Of course, I have no shame. Would someone else? Well we sold a lot of tickets and made money on the raffle. And the winner was stoked on it so I’ll tally it up as a win.