The first test was really successful. My only issues was the softness of the rubber , the fleshtone color (not very A E S T H E T I C) , and how well it stayed attached to the airbox. The original rubber was a urethane compound with a shore hardness of 40A so I ordered some 60A of the same type and orange dye. A quick clean of the mold and I popped another one out.

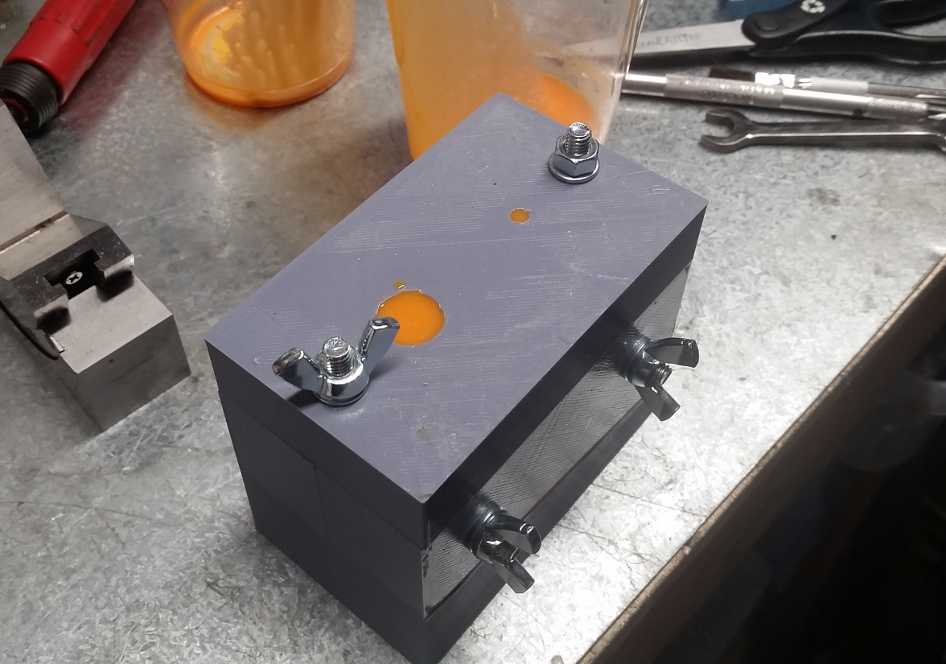

So far I’m finding the actual molding process to be very easy. Prepping the mold for a second pull was only a couple of minutes of cleaning. This time I grabbed a scale to measure the mixture to be a bit more accurate but the process was the same. The new orange color looked great but I didn’t notice a great deal of increases stiffness. One side effect of the dye allowed me to see the rubber surface better and I could see the amount of bubbles in the rubber itself. I think it could be contributing to the relative softness of the rubber. Next step in the process is to get a pressure pot and try to squeeze those bubbles out.

I got a question on insta asking how it compared to a pod filter. I honestly didn’t know because I haven’t had a pod filter for a tomos in years. When I worked at the scooter shop our A55 performance package was a birturbo pipe (look, I know, but they made a pipe that fit with no modifying and no one else did, plus they cheap, no matter how much they suck), a Unipod filter, 35 idle jet, 72 main jet, and a 22T sprocket. It was pretty cheap but would get a nice top speed of about 44mph. It was a setup we put on a lot of bikes and for the most part we were happy with it. I needed to see how this compared to the old setup.

A quick stop down at Scooter Swap Shop and I had a cheap cone filter. So time for test two. First I set my base line with the usual tune of the bike, next I tried the pod filter, then the new velocity stack adapter and the stock airbox. I also downloaded a free gps app for my phone to try a catch a top speed. These are the notes from the session.

Test on a mostly flat and strait section of road next to my house, about a mile out and a mile back. Mid day, temps 79f, sunny, light breeze, low humidity, about 100 ft above sea level. Not tucking, riding upright.

Setting baselines: cut intake tube, stock airbox, 62 main jet, A12 needle 3rd clip down, 35 idle, 2 3/4 turn out. Gearing 26:22. Reached 8260rpm max, 43mph.

1st test pod filter: 76 main, 35 idle, A7 needle, top clip. 43mph max, 8550rpm max.

Low rpms really got slower to accelerate, intake noise was very loud and not a pleasant sound either, top end seemed not much improved, jetting needed to be addressed, had to switch to stock needle to get to run in the middle throttle positions.

2nd pod: 72 main, needle 3rd down ( middle clip), idle screw 1 turn out. 8840 max rpm, max speed said 43, so now I think this app sucks because the math don’t work out, it’s very loud, I witnessed people covering their ears this time out at the highest rpm full throttle, and it’s not a good sound, just a raspy unpleasant noise.

3rd pod: 70 main, needle 4 down, 40 idle, 4 turns out. 8780 max rpm, forgot phone to get gps speed Finally achieved carb smoothness with pod, good idle, snappy response, still slower feeling up to gear shift, starting to get diminishing return of rpm increase with main jet changes, very loud.

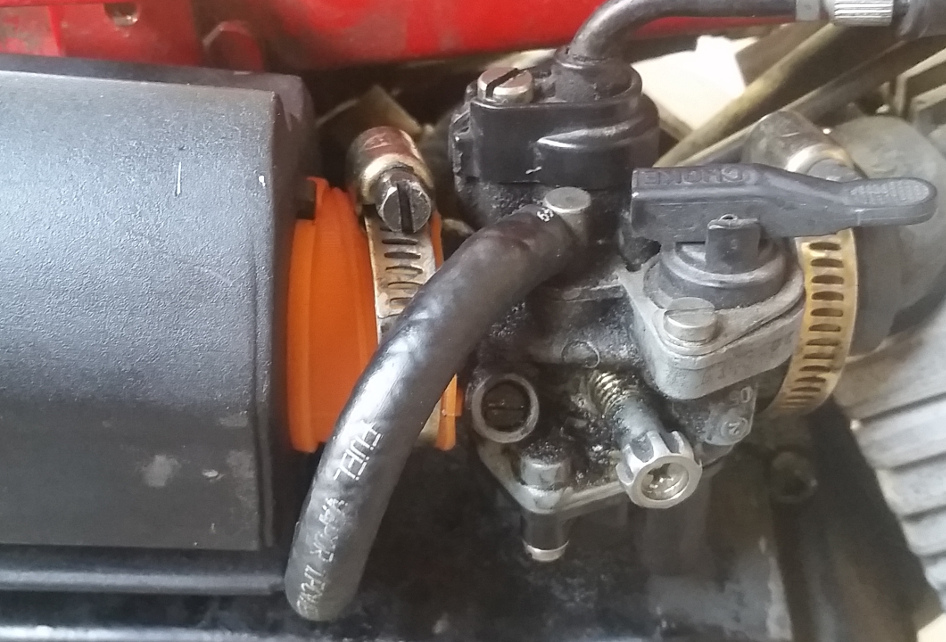

Velocity adapter test 1: 64 main, 35 idle, a12 needle 2nd clip down, 3 3/4 turn out. 8880 max rpm, 44mph on app ( app only says 43 or 44mph, which can’t be right for a almost 1000 rpm swing but whatever) much smoother rpm and off the line. Airbox wouldn’t stay attached to the adapter, kept popping off the lip.

Velocity adapter test 2: tune 62 main, 2 5/8 out 9010 max rpm, 44mph again, this app does not work. Last run had issue of box popping off connector, this run had no issues after aligning it better. Motor feels much stronger all the way through power from off the line to max rpm. Much quieter, I can hear the transmission whine, with the pod I couldn’t hear anything other than the pod filter.

Ok, so lets go over my feeling so far on this. The pod filter so far seems to have a slightly lower max rpm, it felt much slower to get to top speed, it was very loud and annoying to listen to (exhaust notes good, intake notes bad!), and this specific one can’t fit under the side panel so it would get wet and die in the rain ( realize I could just buy a Uni filter and jam it behind there but whatever). The velocity stack adapter used much smaller tuning jets and needle, much quieter, it was easier to jet and find a smoother snappy response. I was expecting the pod filter to have a higher max rpm just because it wasn’t breathing through the airbox intake tube still. That was surprising.

I feel like the acceleration was much better with the velocity adapter and airbox. So a while back I built an arduino device to measure this specific thing so time to pull that out and bolt it on. It measures elapsed time it takes to accelerate between two different speeds. I’ll test the 0-30 and 0-40 time with the best jetting setting for each setup. The part itself needs to be harder still but the 60A is the hardest range of this specific rubber type so I am going to switch to a different compound rubber. I will also build/buy a pressure pot and try to compress the bubbles out of the liquid in the mold. I hope it won’t just squeeze it out of the mold but one issue at a time I guess. I might have to redesign the lip that holds onto the airbox to be a bit more rigid too. Another thought for the future would be to print a new mold with a resin printer. It would be smoother but not super important right now. Anyways, plenty to test out! We’ll get there one step at a time.